Everything You’ll Need

| Tool / Material | Solid Hardwood (Nail-Down) | Engineered Hardwood (Glue-Down) | Engineered Hardwood (Floating/Click-Lock) | Purpose |

|---|---|---|---|---|

| Tape Measure | ✔ | ✔ | ✔ | Measure layout and planks |

| Chalk Line | ✔ | ✔ | ✔ | Mark layout lines |

| Pry Bar | ✔ | ✔ | ✔ | Remove old flooring/baseboards |

| Moisture Meter | ✔ | ✔ | ✔ | Check subfloor moisture |

| Level | ✔ | ✔ | ✔ | Ensure even subfloor |

| Spacers | Optional | ✔ | ✔ | Maintain expansion gap at walls |

| Flooring Nailer / Stapler | ✔ | ✘ | ✘ | Secure solid planks to subfloor |

| Flooring Adhesive | ✘ | ✔ | ✘ | Glue engineered wood to subfloor |

| Trowel (for adhesive) | ✘ | ✔ | ✘ | Spread adhesive evenly |

| Click-Lock Installation Kit | ✘ | ✘ | ✔ | Includes tapping block, pull bar, spacers |

| Miter Saw | ✔ | ✔ | ✔ | Make crosscuts on planks |

| Jigsaw / Oscillating Tool | ✔ | ✔ | ✔ | Trim around obstacles |

| Safety Glasses | ✔ | ✔ | ✔ | Eye protection while cutting |

| Knee Pads | ✔ | ✔ | ✔ | Comfort during install |

| Underlayment / Vapor Barrier | Depends on subfloor/type | ✔ (moisture barrier) | ✔ | Reduces noise & moisture issues |

| Shop Vac or Broom | ✔ | ✔ | ✔ | Keep area clean while working |

Step 1: Prepare the Space

Remove Baseboards and Old Flooring

Start by taking out any old flooring and baseboards to see the subfloor. This gives a smooth surface and lets the new flooring fit well.

Use a pry bar carefully to lift the baseboards without harming the drywall, so you can put them back later. Take out any old floor coverings and make sure to scrape off all glue or staples.

Clean and Level the Subfloor

Sweep and vacuum the subfloor to get rid of dust, nails, and any leftover glue. Check for any dips or bumps with a straight edge or a long level.

- For high spots: sand them down.

- For low spots: use a floor leveling compound to fill and smooth them out.

A flat subfloor is important to stop squeaks and make it last long.

Check for Moisture or Damage

Moisture often causes floor problems. Use a moisture meter to check the subfloor and the planks.

- For wood subfloors: moisture should be below 12%.

- For concrete subfloors: follow specific limits — usually below 4% with a test.

If moisture is too high, don’t start until you fix it.

Install Underlayment or Vapor Barrier (If Required)

You might need an underlayment or moisture barrier, depending on the floor type:

- Over concrete: use a vapor barrier or an underlayment with moisture protection.

- Over plywood or OSB: consider rosin paper, felt, or a foam pad.

Follow the manufacturer’s guidelines to avoid issues and get the best results. Lay it flat without overlap and tape seams as needed.

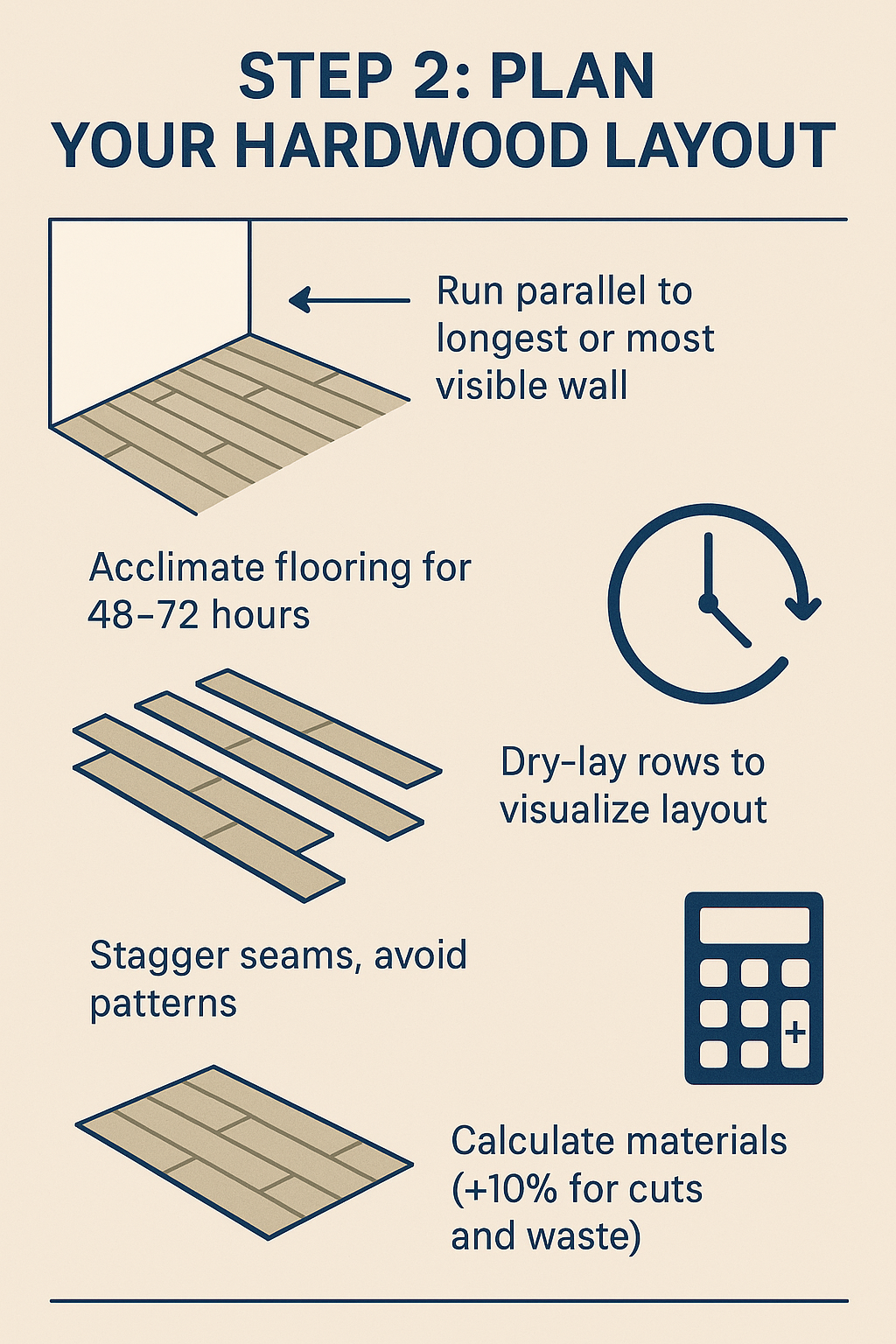

Step 2: Plan Your Hardwood Layout

Choose Your Starting Wall

For most rooms, it’s ideal to lay flooring parallel to the longest or most visible wall—this helps the room look bigger. If working on multiple rooms, think about how planks line up through doorways and transitions.

Use a chalk line to create a straight guideline along your starting wall. This keeps your initial rows straight and ensures the rest of the layout stays aligned.

Acclimate the Flooring

Before you start, let your flooring adjust to the room’s temperature and humidity for at least 48 to 72 hours. Lay the boxes flat in the room where the floor will be installed, and open the ends to let air circulate.

This allows the material to settle in the environment and helps prevent expansion, warping, or gaps after installation.

Dry-Lay a Few Rows

Arrange a few rows of boards without attaching them to see how your layout appears. This helps you:

- Check that the layout looks balanced in the room

- Avoid thin planks near walls

- Plan for obstacles like vents or door frames

Use this chance to mix boards from different boxes to blend color and grain evenly across the floor.

Stagger Seams and Avoid Patterns

To make the floor look natural, stagger the ends of planks by at least 6 to 8 inches in adjacent rows. Avoid repeating the same lengths or forming patterns like “stair-step” or “H,” as these can highlight the seams.

Tip: Change up plank lengths and alternate them across rows for a more natural flow.

Calculate Material (Add Extra for Waste)

Measure the square footage of your area (length × width) and then add 10% for cutting waste, mistakes, and future repairs.

If your space has odd shapes or you’re installing at an angle, increase the waste allowance to 12–15%.

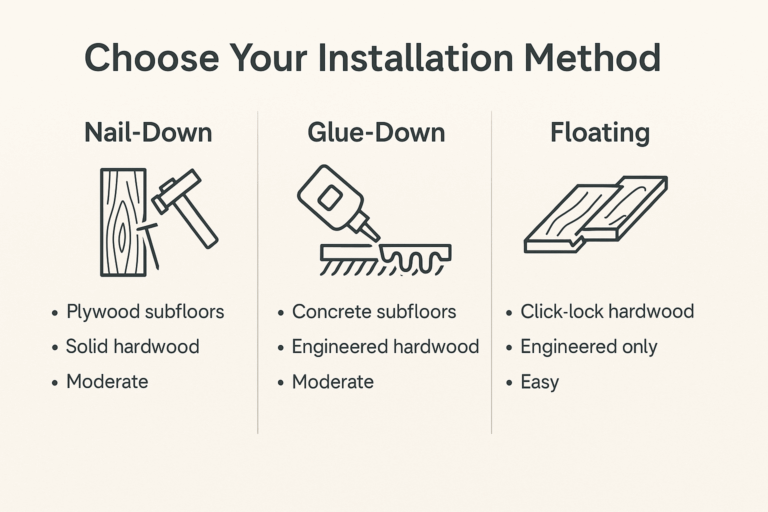

Step 3: Choose Your Installation Method

Before you start laying boards, choose the best installation method for your flooring and subfloor. Each method needs different tools and techniques.

Nail-Down Installation (Common for Solid Hardwood)

Great for solid hardwood on a wood subfloor like plywood. Use a nailer or stapler to attach each board.

- Best for: Solid hardwood on wood subfloors

- Tools needed: Flooring nailer, mallet, air compressor

- Pros: Very secure and lasts long

- DIY Difficulty: Moderate (needs precision and right tools)

Glue-Down Installation

Mainly for engineered hardwood on concrete, apply adhesive to the subfloor and press boards in place.

- Best for: Engineered hardwood on concrete

- Tools needed: Flooring adhesive, notched trowel, floor roller

- Pros: Strong bond, low profile

- DIY Difficulty: Moderate to high (messier, needs ventilation)

Floating Installation (Click-Lock)

Popular for DIYers with click-lock engineered hardwood. Planks lock together and “float” over underlayment without nails or glue.

- Best for: Click-lock engineered hardwood on any flat surface

- Tools needed: Spacers, tapping block, underlayment

- Pros: Fast, clean, beginner-friendly

- DIY Difficulty: Easy

Pro Tip: For solid hardwood over wood subfloors, nail-down is usually best. DIYers like floating floors for engineered hardwood because they are simpler and tool-free.

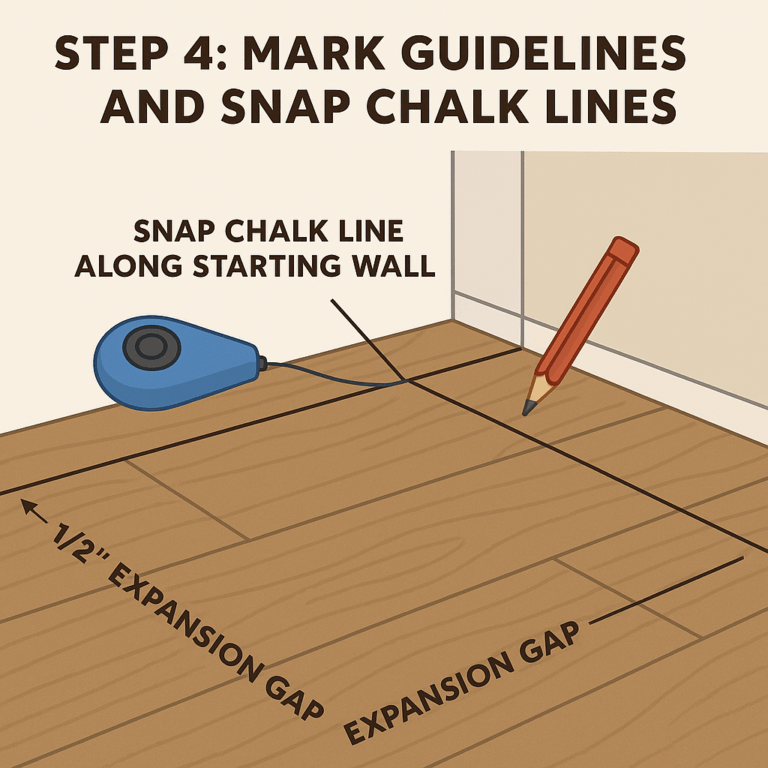

Step 4: Mark Guidelines and Snap Chalk Lines

Before you put down your first board, it’s important to set a straight line to guide you.

Snap a Chalk Line Along Your Starting Wall

Find the starting wall, usually the longest or most visible one. Measure one board’s width, including the gap, and snap a chalk line parallel to this wall. This acts as a guide for your first row.

Use the Line to Keep Rows Straight

When placing the boards, keep lining them up with the chalk line. This helps the flooring stay straight across the room and not curve or drift.

Leave a 1/2″ Expansion Gap Around the Perimeter

Wood changes with humidity. Use spacers to make a 1/2-inch gap between the floor and all surrounding walls, door frames, and other fixed things. This lets the floor expand without bending.

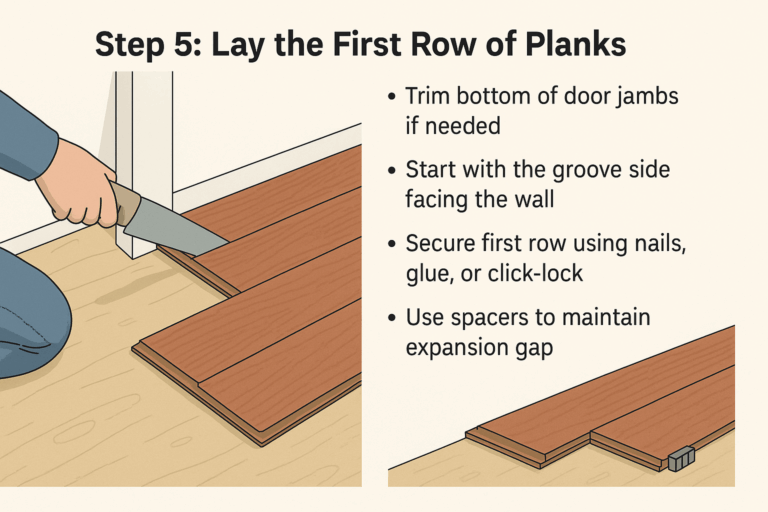

Step 5: Lay the First Row of Planks

Trim Door Jambs if Needed

Before putting down the first plank, see if it needs to slide under any door frames or trim. Use a saw to trim the bottoms of door jambs so the planks fit neatly underneath without leaving gaps.

Start with Groove Side Facing the Wall

Place the first plank with the groove side toward the wall. This helps the tongue of the next row lock into place easily. Start on the longest, straightest wall in the room to keep the flooring lined up nicely.

Secure the First Row

Depending on how you install:

- Nail-down: Use a nailer to fasten the boards into the subfloor through the tongue side.

- Glue-down: Spread glue with a trowel and press each plank firmly in place.

- Floating (click-lock): Angle the second plank into the first and click to lock.

Make sure the planks fit tight against each other without gaps.

Use Spacers to Maintain Expansion Gaps

Insert 1/2″ spacers between the planks and the wall. This gap lets the flooring naturally expand and contract due to humidity and temperature changes, stopping buckling or warping over time.

Step 6: Install the Remaining Flooring

After the first row is set and straight, keep laying the planks row by row.

Stagger the End Joints for Stability

For a natural look and strength, make sure the ends of each row are at least 6 inches apart. Don’t line up the joints in a row, as this weakens the floor.

Use a Tapping Block for a Tight Fit

Put a tapping block on the edge of each plank and lightly tap it with a mallet to close gaps. This keeps each board snug without harm.

Secure Boards Based on Your Method

- Nail-down: Nail through the tongue at a 45° angle every 6–8 inches.

- Glue-down: Spread glue evenly and press planks firmly.

- Floating floor: Click boards together end-to-end and side-to-side.

Check for Level Frequently

Every few rows, use a level to keep the floor flat. Adjust if needed to avoid issues later.

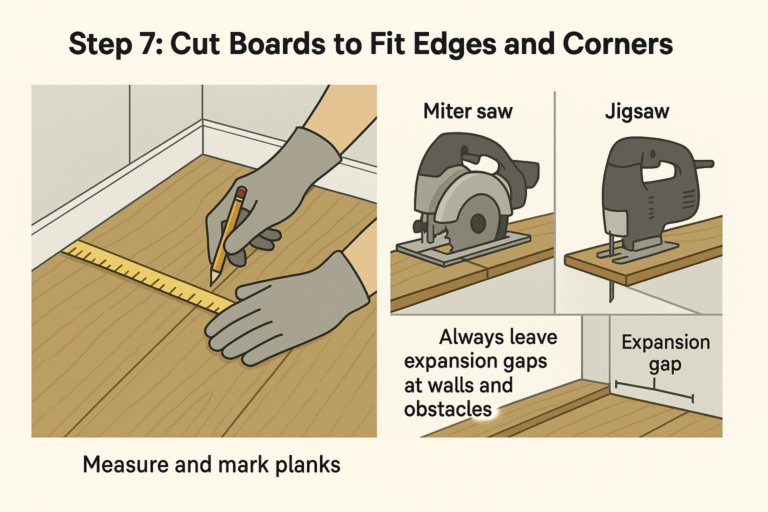

Step 7: Cut Boards to Fit Edges and Corners

When you get to walls or things in the room, cut the last planks to fit right.

Measure and Mark Carefully

Use a tape measure to find the exact space left, taking away 1/2″ for an expansion gap. Mark the plank with a pencil or chalk.

Use the Right Saw for the Job

- Miter saw: Best for straight cuts.

- Jigsaw: Good for cutting around vents, door frames, or odd shapes.

Always cut on a stable surface and wear safety glasses to keep eyes safe from dust.

Maintain Expansion Gaps

Leave a 1/2″ gap between flooring and all vertical surfaces like walls and pipes. This helps the flooring expand and contract naturally.

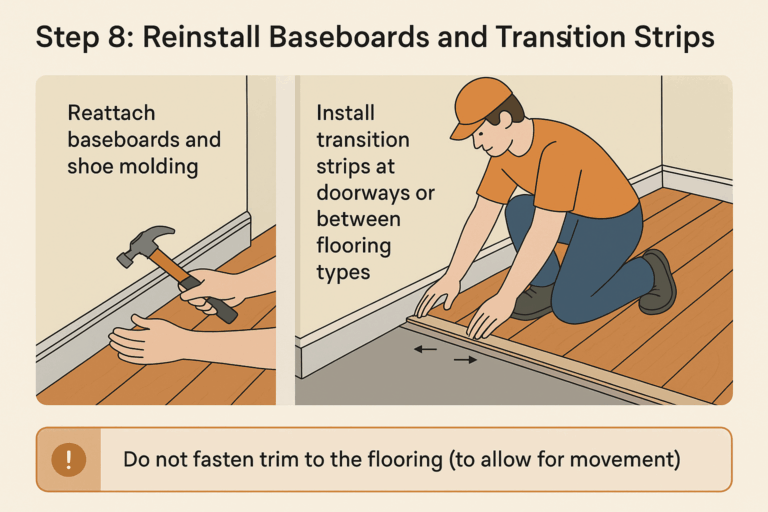

Step 8: Reinstall Baseboards and Transition Strips

Reattach Baseboards and Shoe Molding

After installing your new flooring, put back the baseboards around the room. If you had shoe molding before, add it again for a neat finish.

Install Transition Strips

In doorways or where different floors meet (like tile), add transition strips. Use T-moldings, reducers, or threshold transitions based on the floor height and material.

Leave Room for Movement

When fastening trim, do not attach it directly to the flooring. This allows the floor to expand and contract without issues. Secure the trim to the wall or subfloor instead of the floating floor.

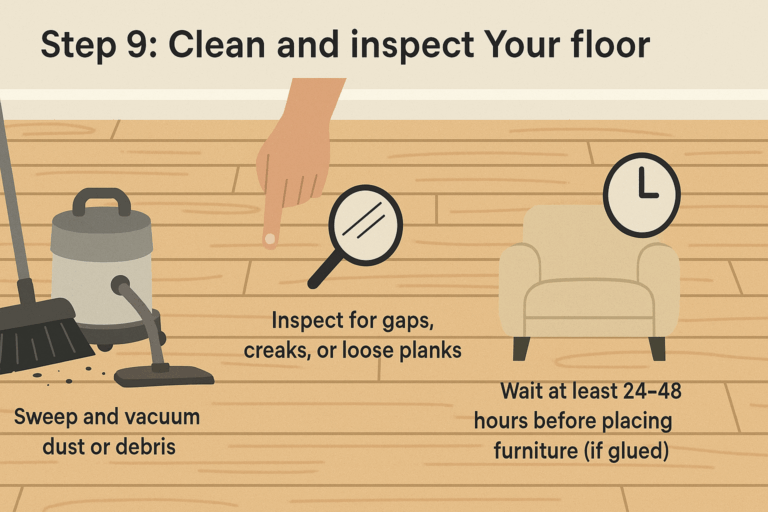

Step 9: Clean and Inspect Your Floor

After installation, clean and check your new floor to make sure it’s ready to use.

Sweep and Vacuum Well

Use a broom or a vacuum with a soft brush to remove any dust or debris. This helps you see the floor clearly and prevents scratches.

Look for Problems

Check for gaps, uneven boards, or noises when you walk. Use a tapping block to fix misaligned boards or follow your installation guide for adjustments.

Allow the Floor to Settle

If you used glue, wait 24–48 hours before adding furniture or rugs to let the adhesive cure properly.

Pro Tips for a Successful Hardwood Installation

Achieving a professional look with flooring requires preparation and care. These tips can help you work better:

- Test for moisture using a moisture meter before starting — this prevents future problems.

- Wear knee pads to protect yourself, and ensure good ventilation if using glue.

- Check alignment every few rows to keep everything straight.

- Work in small sections instead of rushing — this keeps quality high.

- Be careful with cuts. Clean cuts are important for tight seams and a good finish.

Common Mistakes to Avoid

Even skilled DIYers can make mistakes if they’re not careful:

- Skipping the acclimation period can make wood expand or shrink later.

- Ignoring subfloor moisture and flatness can cause problems like noise or gaps.

- Not staggering seams can weaken the floor and look uneven.

- Nailing too close to the edge can cause splitting.

- Forget to use spacers and the floor may buckle because it can’t expand.

DIY vs. Professional Hardwood Installation

Installing flooring by yourself can save money and be fun, but it’s not for everyone. Here’s how to decide if you should do it yourself or get help.

DIY Pros:

- Lower project cost

- Control over time and pace

- Pride in doing it yourself

DIY Cons:

- Hard work and takes time

- Needs planning and special tools

- Fixing mistakes can be expensive

Professional Installation Pros:

- Quick, expert work with little disruption

- Includes prep, leveling, and cleanup

- Usually has warranties

Professional Installation Cons:

- Higher labor cost

- Less control over timing

📊 Side-by-Side Comparison Table

| Feature | DIY Installation | Professional Installation |

|---|---|---|

| Average Cost per Sq Ft | $3 – $8 (materials + tools) | $7 – $18 (includes labor) |

| Best For | Budget-savvy, handy people | Busy people, big or complex jobs |

| Time Commitment | Several days or weekends | 1–2 days (typical) |

| Risk of Mistakes | Moderate to high | Low |

| Tool Investment Required | ✔ | ❌ (provided by installer) |

| Satisfaction | High (if done well) | High (with professional finish) |

👉 For a full breakdown of costs, methods, and scenarios, visit our Hardwood Flooring Cost Guide

Do You Need Professional Help With Your Hardwood Flooring Installation Project?

Now that you’ve learned how to install flooring step-by-step, you’re ready to create a beautiful look that adds value to your home. But if you’d like to avoid the hard work, we’re here to help.

Our expert flooring installation team takes care of everything with precision. We’ll ensure your floor is even, sturdy, and long-lasting — without you having to do the work.

Contact us today to schedule your free in-home consultation and see if we serve your area!